Creating a model railway station is a rewarding hobby that combines craftsmanship, technology, and a keen eye for detail. To build a model railway station that stands out, hobbyists must understand and utilize various tools and components. This article will explore four key aspects essential to enhancing your model railway station: Mach4 CNC controllers, stepper motor current, flat cable cutters, and model railway stations themselves.

Mach4 CNC controllers are vital for precision and automation in crafting detailed railway components. Stepper motor current is crucial for ensuring smooth and accurate movement of trains and other moving parts on your layout. Flat cable cutters are indispensable tools for cleanly and efficiently managing the wiring that powers your setup. Lastly, understanding the intricacies of a model railway station helps in creating a realistic and functional miniature world.

By diving into these topics, you’ll gain the knowledge needed to take your model railway station to the next level, ensuring both functionality and aesthetic appeal. Let’s delve into each of these components and discover how they interconnect to bring your model railway station to life.

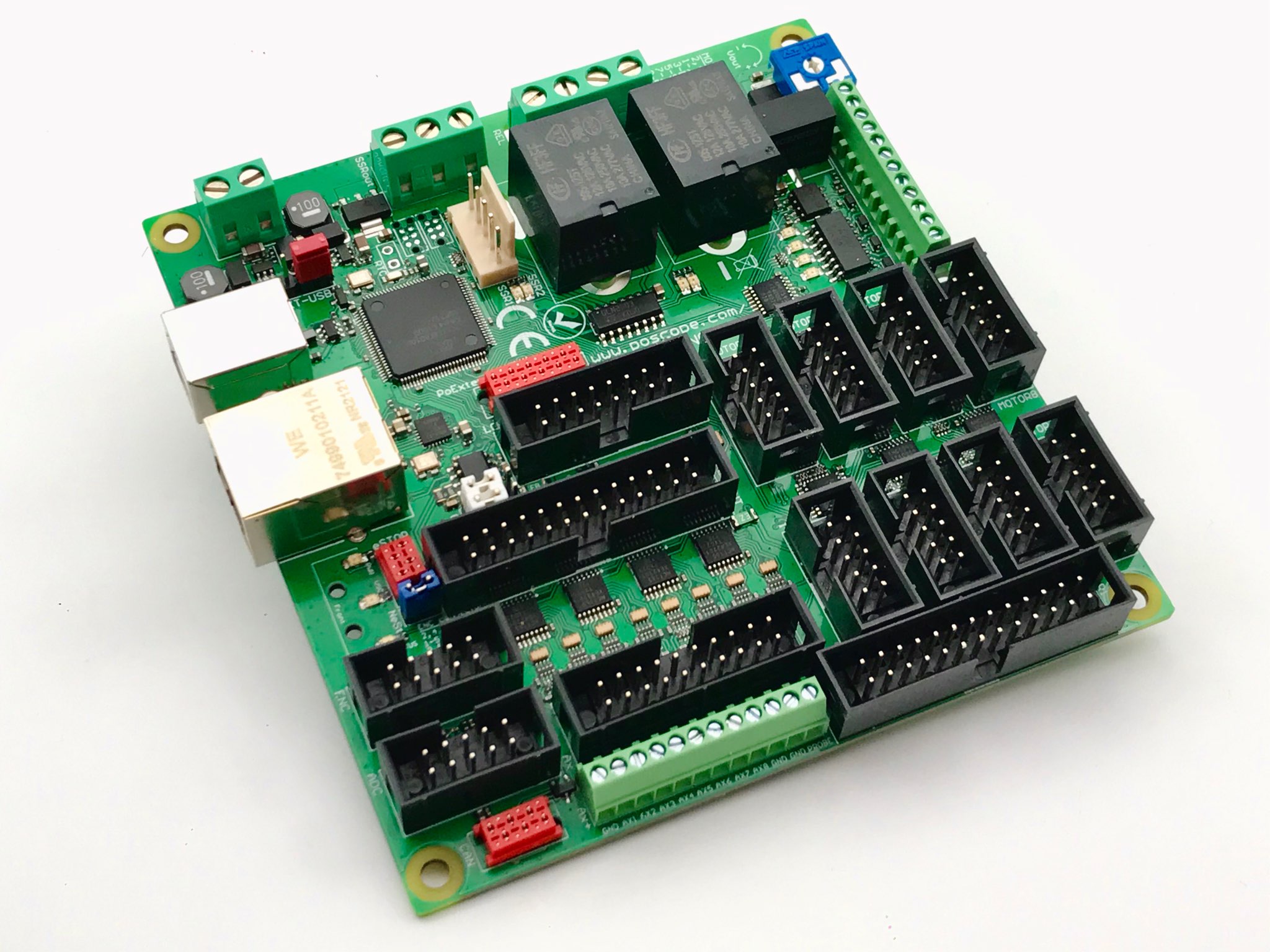

Mach4 CNC Controller

The Mach4 CNC controller is a pivotal component for hobbyists aiming to achieve precision and efficiency in their model railway station projects. Developed by Newfangled Solutions, the Mach4 CNC controller offers advanced features that cater to both novice and experienced users. This controller is designed to manage various types of CNC machines, including those used to craft intricate model railway components.

One of the key benefits of the Mach4 CNC controller is its high level of customization. Users can tailor the software to meet the specific needs of their projects, allowing for greater control over the cutting, shaping, and assembly processes. This level of customization ensures that each component of your model railway station is crafted with exact precision, enhancing the overall realism and functionality of the setup.

In addition to customization, the Mach4 CNC controller is known for its robust performance. It supports multi-threading, which means it can handle multiple tasks simultaneously without compromising on speed or accuracy. This feature is particularly useful when creating detailed parts that require complex machining operations. With the Mach4 CNC controller, users can efficiently produce high-quality components, saving time and reducing the likelihood of errors.

Another notable feature of the Mach4 CNC controller is its user-friendly interface. The software is designed to be intuitive, making it accessible for users with varying levels of technical expertise. Detailed tutorials and a supportive user community further enhance the learning experience, enabling hobbyists to maximize the potential of their CNC machines.

Overall, the Mach4 CNC controller is an essential tool for model railway enthusiasts who seek precision and efficiency in their projects. By leveraging its advanced features and customization options, you can create intricate and accurate components for your model railway station, ensuring a professional and polished final product.

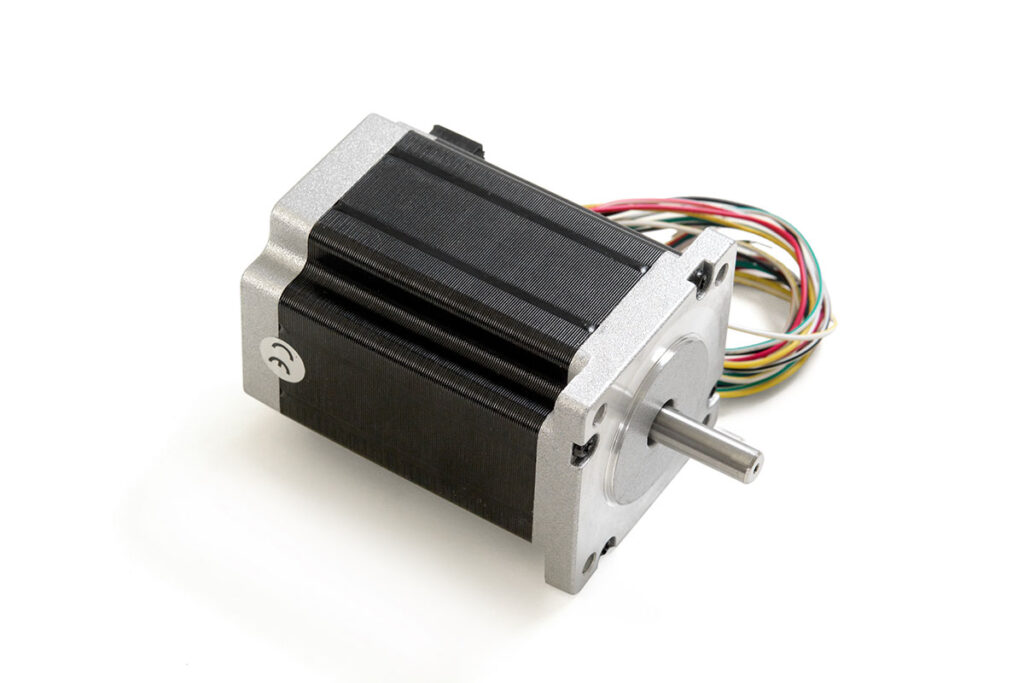

Stepper Motor Current

When building a model railway station, understanding and managing stepper motor current is crucial for achieving smooth and precise movement. Stepper motors are widely used in model railways to control the motion of trains, turnouts, and other moving components. These motors operate by dividing a full rotation into a series of discrete steps, allowing for accurate positioning and control. However, to get the best performance out of your stepper motors, you need to properly manage their current.

Stepper motor current directly affects the motor’s torque and speed. If the current is too low, the motor may not generate enough torque to move the components effectively, leading to stalls or missed steps. Conversely, if the current is too high, the motor can overheat, which may damage both the motor and the driver circuitry. Therefore, it is essential to strike the right balance by setting the appropriate current for your specific application.

Most stepper motor drivers, including those used in model railway stations, allow you to adjust the current settings. This adjustment can typically be done through software, such as the configuration settings in the Mach4 CNC controller, or through hardware, by adjusting potentiometers on the driver board. When setting the current, it is important to follow the manufacturer’s guidelines and start with lower settings, gradually increasing the current until optimal performance is achieved without overheating.

Proper cooling is also essential for maintaining the longevity and performance of stepper motors. Heat sinks and cooling fans can be used to dissipate heat generated by the motors and drivers, ensuring they operate within safe temperature ranges. Regularly monitoring the temperature of your stepper motors and drivers can prevent overheating and extend their lifespan.

In summary, managing stepper motor current is vital for ensuring smooth and accurate movement in your model railway station. By carefully adjusting the current settings and providing adequate cooling, you can optimize the performance of your stepper motors, resulting in reliable and precise operation of your model railway components. This attention to detail will significantly enhance the overall functionality and realism of your model railway station.

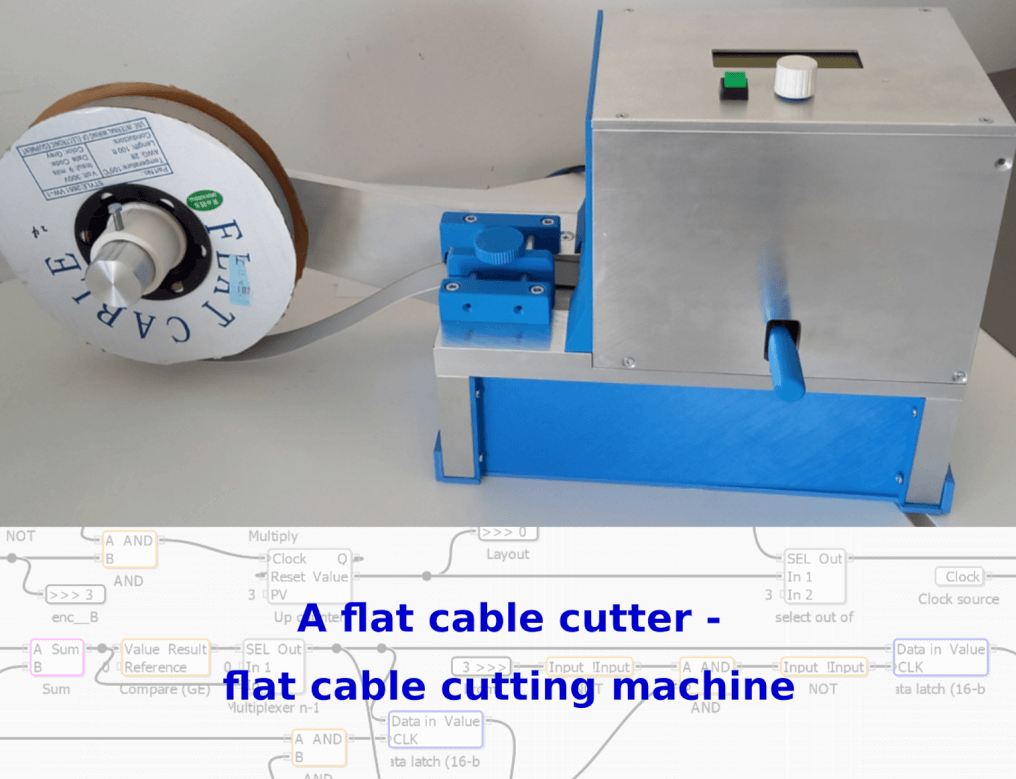

Flat Cable Cutter

A flat cable cutter is an indispensable tool for model railway enthusiasts who want to keep their wiring neat and functional. Managing the complex network of wires that power your model railway station can be challenging, but a flat cable cutter makes the task much more manageable. This specialized tool is designed to cut flat ribbon cables cleanly and accurately, ensuring that your wiring is precise and organized.

Flat ribbon cables are commonly used in model railways due to their compact and flexible nature. They can be easily routed through tight spaces and around complex layouts without taking up much room. However, cutting these cables with traditional tools can result in frayed ends and uneven cuts, leading to potential connectivity issues. A flat cable cutter solves this problem by providing clean, straight cuts every time.

Using a flat cable cutter is straightforward. The tool typically features a sharp, durable blade and a guided mechanism that ensures the cable is held securely in place during cutting. This design minimizes the risk of damaging the cable or creating uneven cuts. Some flat cable cutters also come with adjustable guides, allowing you to cut cables of various widths accurately.

The precision offered by a flat cable cutter is essential for maintaining the integrity of your electrical connections. Clean cuts ensure that the exposed wires make proper contact with connectors, reducing the likelihood of signal loss or electrical interference. This reliability is crucial for the smooth operation of your model railway station, where even minor connectivity issues can disrupt performance.

In addition to improving the quality of your cuts, a flat cable cutter also enhances safety. Frayed cables can pose a risk of short circuits, which can damage your components or even cause fires. By using a flat cable cutter, you can eliminate these risks, ensuring a safe and efficient wiring system for your model railway station.

In conclusion, a flat cable cutter is a valuable tool for anyone serious about building a high-quality model railway station. By investing in this tool, you can achieve precise, clean cuts that enhance both the functionality and safety of your wiring system. This attention to detail will contribute significantly to the overall success of your model railway project.

Model Railway Station

A model railway station serves as the heart of your miniature railway system, combining both functional and aesthetic elements to create a realistic and engaging experience. Crafting a model railway station involves meticulous planning and attention to detail, ensuring that it not only looks authentic but also operates smoothly. This chapter delves into the key components and considerations for building an impressive model railway station.

First and foremost, the layout design of your model railway station is critical. The design should reflect the era and location you are aiming to replicate, whether it’s a bustling urban terminal or a quaint rural stop. Careful planning of track placement, platform arrangements, and surrounding structures can significantly enhance the realism of your station. Tools like Mach4 CNC controllers can aid in precisely crafting custom track segments and station components, ensuring a seamless and accurate layout.

Another essential aspect of a model railway station is the integration of electrical and mechanical systems. This includes the wiring, which connects various elements like lights, signals, and motors that control the movement of trains and turnouts. Using a flat cable cutter ensures that your wiring is neat and efficient, reducing the risk of connectivity issues that could disrupt your railway’s operation. Properly managed stepper motor current is also crucial here, as it guarantees the smooth and reliable movement of trains within the station, adding to the overall realism.

Scenery and detailing bring your model railway station to life. Adding realistic features such as benches, passengers, signage, and foliage can transform a simple track layout into a vibrant, bustling station. High-quality models and accessories are available from various suppliers, or you can use CNC machining to create custom pieces that fit your specific vision. Paying attention to small details, like weathering effects on buildings and tracks, can further enhance the authenticity of your station.

Lastly, operation and maintenance are vital for keeping your model railway station in top condition. Regular checks on the electrical systems, ensuring that stepper motors are functioning correctly and that all connections are secure, can prevent issues that might affect performance. Keeping the tracks clean and free of debris is also essential for smooth train operation.

In summary, building a model railway station involves a blend of creative design and technical expertise. By focusing on layout planning, integrating reliable electrical systems, adding realistic details, and maintaining your setup, you can create a model railway station that is both visually stunning and operationally sound. This attention to detail will not only enhance your enjoyment of the hobby but also impress anyone who sees your miniature masterpiece.

Conclusion

In conclusion, creating a model railway station that stands out involves mastering several key components: Mach4 CNC controllers, stepper motor current management, flat cable cutters, and the intricate details of the station itself. The Mach4 CNC controller offers precision and customization, essential for crafting detailed components. Proper management of stepper motor current ensures smooth and reliable movement of trains. A flat cable cutter is invaluable for maintaining a clean and efficient wiring system. Finally, thoughtful design and detailing of the model railway station bring the entire setup to life.

By understanding and implementing these elements, you can elevate your model railway station to new heights of realism and functionality. This comprehensive approach not only enhances the visual appeal but also ensures a seamless and enjoyable operation, making your model railway station a true work of art.